automation in Moldflow

with the moldflow toolbox

CodePS engineers always question and try to improve the status quo of product development. This is why improving our workflows by automation and optimization is such an important part of our philosophy. That is why we developed the moldflow toolbox.

the challenge

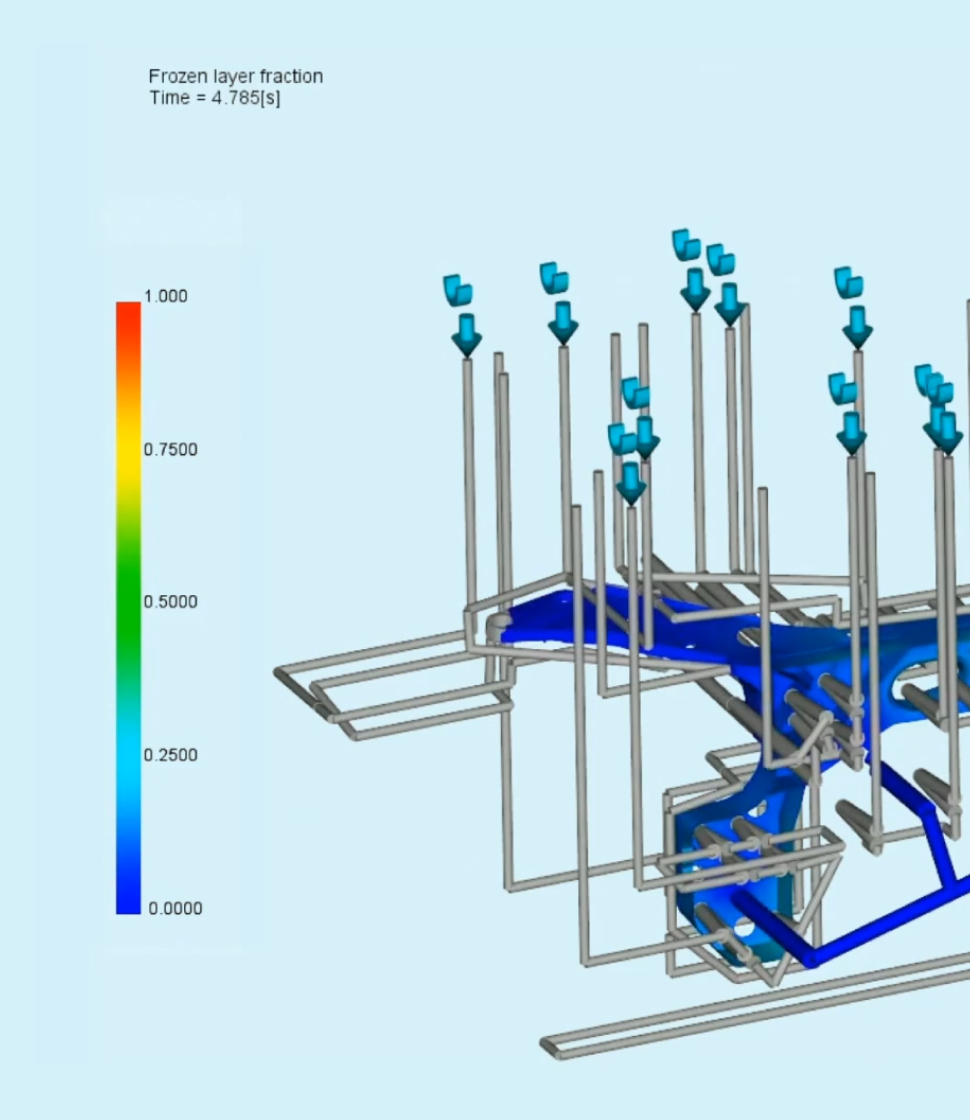

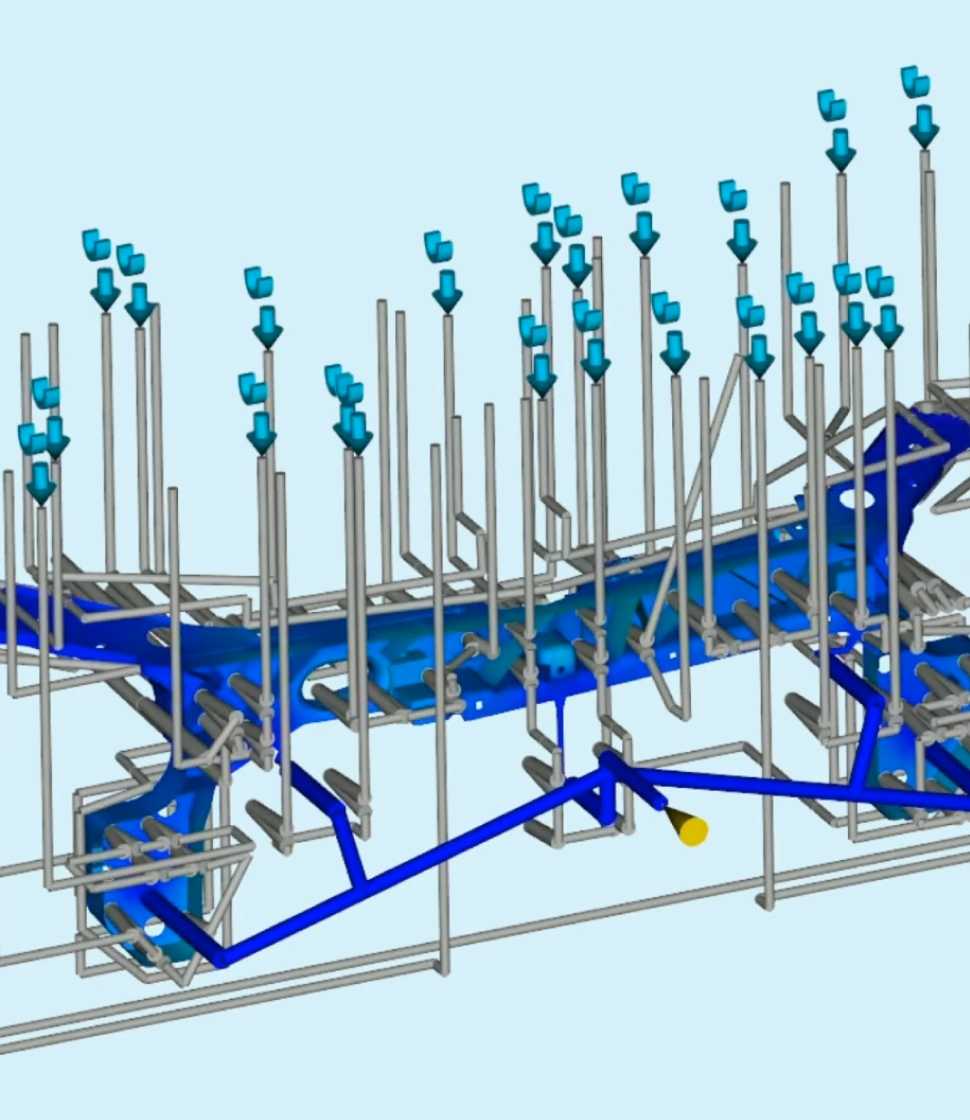

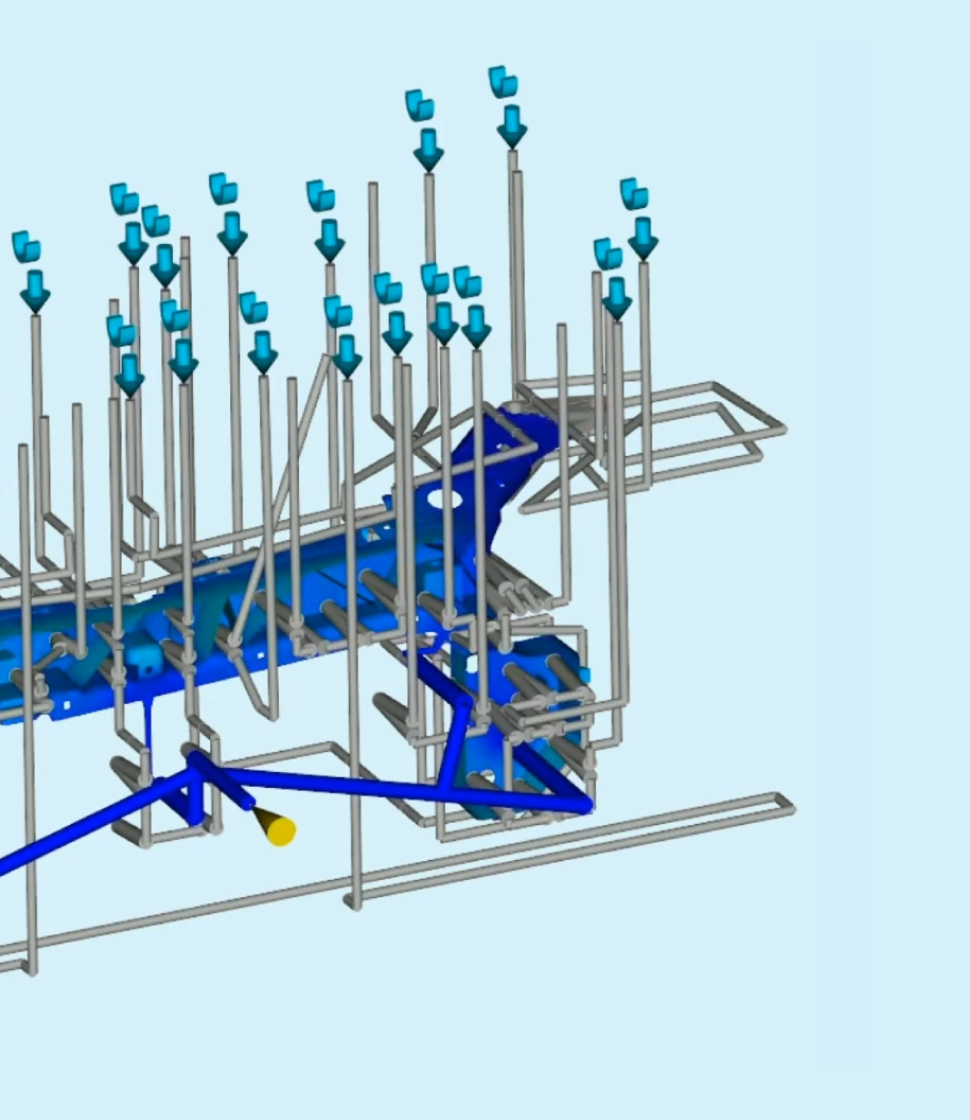

Moldflow was the very first software acquired at CodePS. Our engineers built up their experience in plastic part development for more than 17 years and worked on countless applications – to understand rheological performance and draw conclusions to design and produce better products.

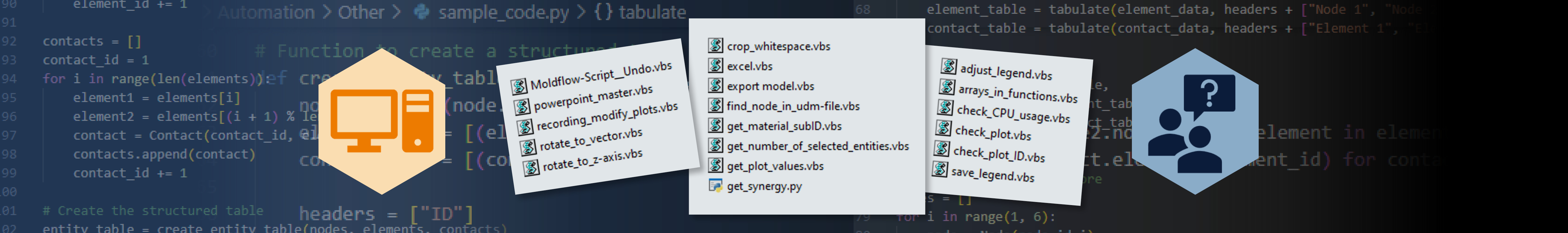

To enhance efficiency, we created automation scripts to streamline repetitive tasks. However, as these scripts were stored across different systems with varying versions, it became difficult to track, share, and customize them effectively. To optimize our processes and ensure that valuable knowledge was preserved and accessible, we set out to centralize and standardize these scripts, enhancing collaboration and improving efficiency across our team.

the process

- To streamline activities, CodePS created the moldflow toolbox. All scripts were gathered on a centralized server, versioned and assigned to someone for further development management.

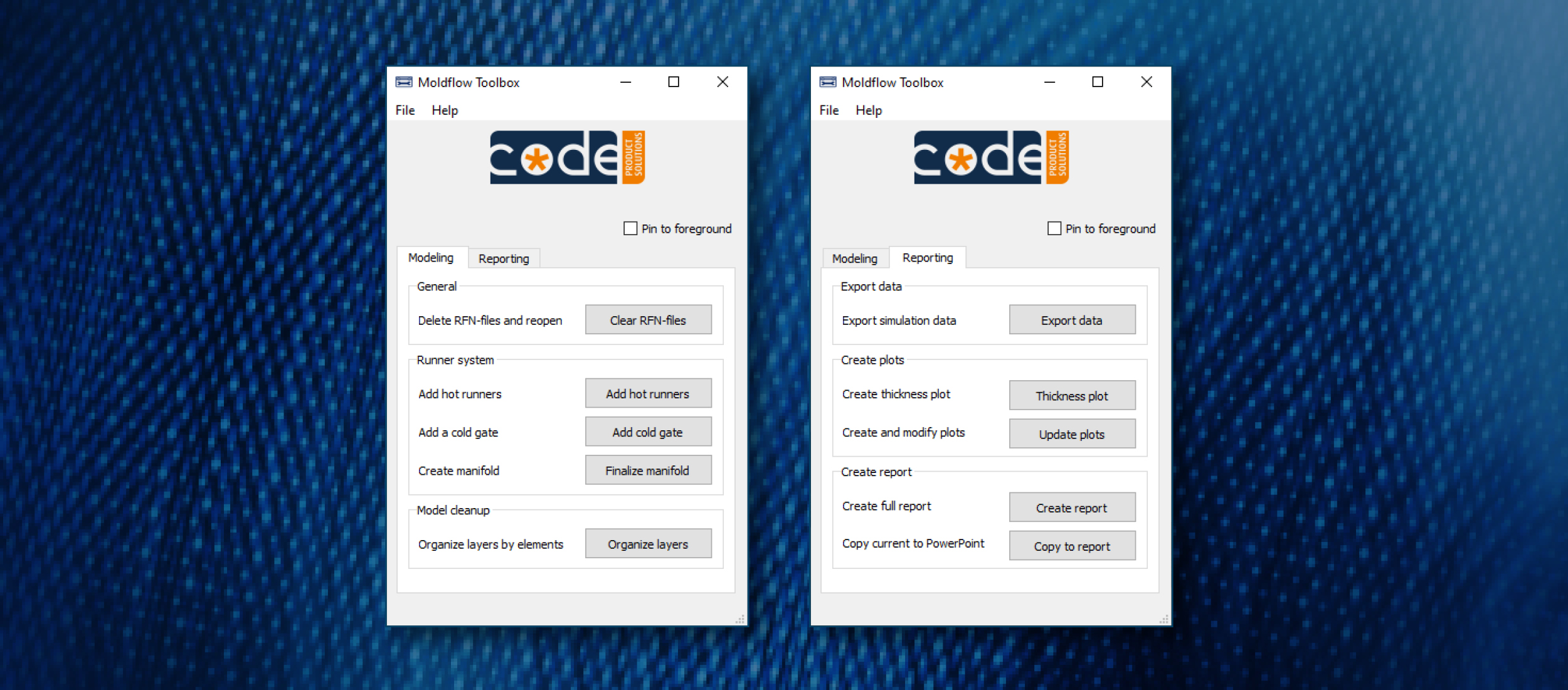

- To overcome the challenge of making the scripts modular and re-usable we developed user interfaces that allowed simple modifications.

- All scripts and their responding dialogs were gathered in one main UI which was internally referred to as the moldflow toolbox.

the result

The moldflow toolbox streamlines tasks like adding runners, checking results, and generating reports—saving several hours per project. It boosts project throughput, improves consistency, and enhances quality and documentation, all while reducing frustration from repetitive tasks.

Renowned companies like SABIC, B/S/H, Aptiv, and Polytec save thousands of hours every year thanks to the moldflow toolbox. Ready to transform your workflow? Let’s talk!

“The Moldflow toolbox enables us to lower lead time by several hours per project and, in addition, increase quality.”

Sebastian Forster

Head of Simulation, BSH Hausgeräte GmbH

services in this project

48h simulation service

concept development

manufacturability studies

scripting

simulation technology

structural finite element analysis